Pumps in general

Drilling trunks lengthways is a technical feat in woodworking, requiring thorough wood and material knowledge. Hollowed out logs have traditionally been used for a variety of applications. The MOT has a few wooden water pipes in the collection, as well as a rare wooden liquid manure pump. An important application is the water pump. For centuries you found it on many farmyards, near the house, but also on the village square or in the city center. Such wooden pumps were essential in everyday life, to obtain drinking water for both man and animal, to prepare food, for the dishes, for cleaning, but also for all kinds of professional activities. Wooden water pumps provided fresh and clear water if they were carefully manufactured and installed.

The emergence of metal pumps and pipes in the nineteenth century ment that fewer and fewer wooden examples were made. After the widespread distribution of drinking water in the second half of the twentieth century, the use of wells and pumps declined rapidly. Many wells are now closed and pumps are demolished. Along with the architectural heritage, the knowledge associated with drilling, installing and using wooden water pumps is also nearly lost. By sharing this knowledge, we hope to upgrade this heritage albeit small but with great historical, environmental and technical value.

video: wooden water pipes in collection MOT (Dutch spoken)

video: a rare wooden liquid manure pump in collection MOT (Dutch spoken)

The craft of pumpmaking in Flanders

In Flanders, the pumpmaking craft is mainly known in the West of Flanders. Various heritage collections contain hand tools and images of pumpmakers from the region. The tools were often passed on from father to son for generations. The concentration of pumpmakers in West Flanders and the Meetjesland can be explained by the soil conditions and the limited depth of the groundwater, which made it possible to use the pump, made from a tree trunk of four meters. In areas where the groundwater is deeper, open wells with windlass were previously installed. It also seems unlikely that in certain villages many water pumps were produced to supply the rest of Flanders. This may be possible for wooden bear pumps.

The craft was a secondary activity rather than a main activity and was often combined with that of a cartwright or carpenter, because of the parallels in tools and working method. For example, when drilling out the hub hole, a cartwright also uses a series of wide scallop irons to clear a hole in the wood. The combination mill builder and pumpmaker was also found in West Flanders, as the central stake in a post mill and other mill parts were also hollowed out lengthwise. In many shipyards, the combination with mast and block making industry occurred, including in Friesland and Holland.

The practice of pumpmaking and its tools in Flanders is somewhat comparable to regions in the Netherlands, Northern France and England, where hardwood such as oak and elm was used as well. Elsewhere in Europe, especially in the Alps and the central mountains of Germany and France, coniferous wood was traditionally used. For this, shorter screw augers with a different shape and construction are used. The spiral shape at the end pulls the auger into the wood.

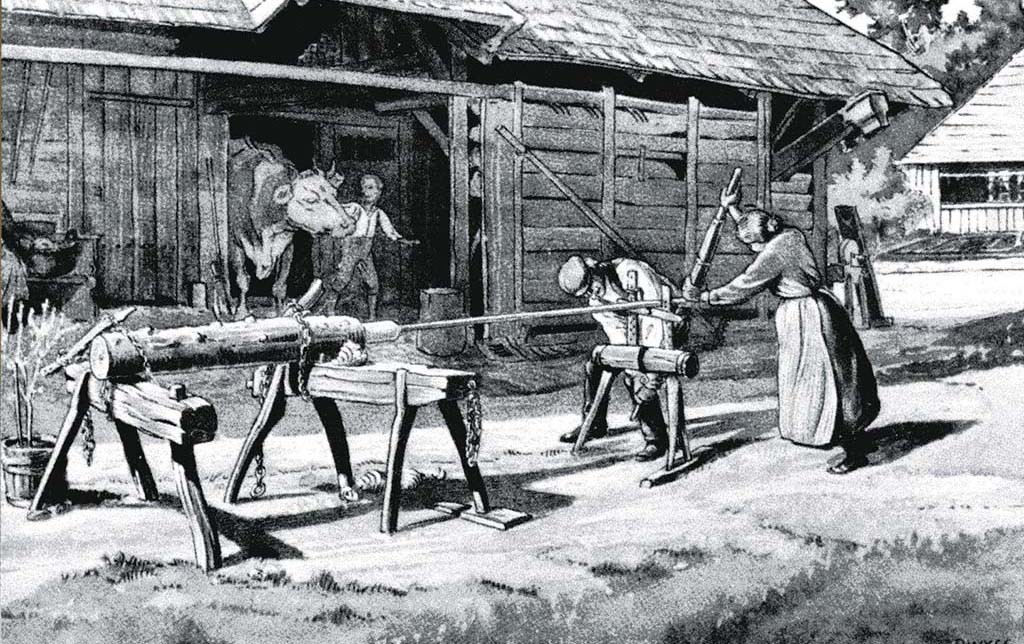

Early on, mechanized solutions were devised for heavy drilling. For example, the drill bits were driven by a water mill and more recently a motor was coupled to the drilling rig. Some of these installations still function, for example in Germany. Mechanization mainly took place during large-scale work, such as water supply networks in softwood or elm.

Hand tools

The specific equipment of the pumpmaker consisted mainly of hand tools to pierce the tree trunk, the long pump auger with wooden crank and all kinds of extensions, bits and enlarging plates on the pump rip bit. These specialised drilling tools were originally manufactured by the local blacksmith. On a larger scale, most examples were probably forged in the major metal tool manufacturing centers such as Remscheid and Sheffield. The pumpmaking rig also included trestles, clamps for securing the trunk and measuring tools such as the chalk line.

However, there are many other processes involved in the making of a wooden pump. To this end, the pumpmaker used various sets of hand tools or enlisted the help of other specialised professionals. For example to cut down, transport and square the trunk. For turning the parts for the pump interior, he used a lathe with accompanying tools. To dig and build a new well, the help of a well digger or a bricklayer was called in.

Various applications

The knowledge on how to pierce wooden trunks lengthwise was already present in ancient times and until the mid-twentieth century many applications were still very common. Elsewhere in the world, water wells and wooden pumps are still current practice.On the one hand, all kinds of woodworkers were able to hollow out wooden trunks lengthwise, to use as verticals in large wooden structures. Just think of ship's masts, columns, piles for damming or the central stake and axle in a windmill. Hollowing out a beam helps prevent splitting and bending, among other things.

On the other hand, there are many applications for transporting or pumping liquids:

- Archaeologists and road workers all over the world have found the remains of huge wooden water supply networks. In London, for example, a complete water supply network was once constructed in elm wood.

- Water supply for craftsmen and industrial applications such as paper mills, breweries, tanneries, ice and lemonade factories...

- Fountaineers originally used wooden trunks to supply fountains

- Liquid manure was pumped out of the cesspool with a liquid manure pump. Its construction is very similar to a water pump but it's borehole has a larger diameter, the section above ground is higher and the crank lever is longer.

- Pumps in a basement of an oil mill to pump vegetable oils (colza, rapeseed, linseed) back to the top after pressing. In the Netherlands examples of such windmills with wooden oil pumps have been preserved.

- Ship pumps / bilge pumps on ships to pump the excess bilge water from the lower holds to sea level and overboard. The well-known sailing ship Batavia in Amsterdam, for example, has three.

- Mine pumps were used to discharge excess groundwater from low-lying corridors

- In salt mines wooden pumps and pipes were used to pump up salty water to ground level to heat up and evaporate