Creating a design

Then and now

In the heyday of half-timbered construction, several types of half-timbered buildings were built. Houses in the city and in the countryside, barns, stables, ashes, bakehouses, grain nails, wagon sheds, dovecotes, water mills... even half-timbered chapels were found. All these buildings were designed with certain factors in mind: available raw materials, financial resources of the client, function, traditions, climatic conditions… They all had an influence on the design and implementation. These aspects also play a role in contemporary half-timbered construction. What type of building do we want to build? What should it be for? How much material and energy can and do we want to invest in it? A half-timbered structure for a contemporary home will of course have to meet different requirements than a clay playhouse or sheep stable.

To get inspired

Making a good design is not easy, but it is very important to achieve a good result. The best inspiration to start a construction plan are the old half-timbered structures that are still preserved, in situ or in open-air museums. In addition, photos, drawings and rare measurement plans of half-timbered buildings can also be the starting point for a new design. Finally, there are numerous manuals for the carpenter in which you can find principles and drawings of trusses.

Choosing the right proportions

Proportions are very important in a craft. For example, if you want to make a smaller version based on an existing building, you must also reconsider the cross-section of the beams. For smaller spans the beams may be thinner. If you don't do that, the building will undoubtedly be strong, but look very bulky. Structural wood has been a valuable commodity for a very long time and therefore beams that were unnecessary or too heavy were rarely used. On the other hand, you cannot simply enlarge an existing truss or adjust a roof slope.

Adapting the design to today's standards

Anyone who wants to build a traditional half-timbered structure whose use is very close to historical use (for example a sheepfold in a nature reserve) should stay as close as possible to the original construction techniques, materials and designs. But if contemporary standards, for example for comfort, can be achieved, then you have to view the historic design from a contemporary perspective. The wall structure for a modern half-timbered house will not be the same as that of a house from approximately 100 years ago and the half-timbered structure must also be adapted accordingly. Maintaining what is good about tradition and innovating where necessary is a great challenge. This is what MOT is trying to achieve with the design of the new half-timbered workshop.

The wooden structure of a half-timbered building must be designed based on the foundation, the floors, the wall filling (insulation, utility pipes) and the roof covering (slope, load-bearing capacity, flexibility). You have to think carefully about all these elements in advance and make the right and decisive choices.

The best ideas come during the breaks

The plans for the workshop are discussed

Drawing out the roof structure of the nativity scene

Drawing to determin the slope of the roof

Foundation

The easiest way to erect a wooden structure is to drive the posts directly into the ground. Prehistoric houses were built in this way, resulting in the many post hole marks that remained in the soil. However, wood in contact with the soil is quickly affected by fungi and insects. That is why people gradually started to create above-ground wooden structures, which, thanks to triangles and wooden connections, had sufficient strength to rest on a foundation. To ensure sufficient load-bearing capacity, natural stone or brick is used, ranging from loose cobblestones in a ditch to a massive stone plinth. Free-standing posts, such as those inside a barn, are placed on a square column made of natural stone or brick. The bearing capacity of the soil, the weight and windage of the structure and the requirements of the structure determine the shape of the foundation. Contemporary half-timbering can, for example, also be founded on screw piles or concrete blocks, or on concrete posts as in the half-timbered workshop.Stability

An important principle in truss construction and construction theory in general is that triangles are not deformable, unlike squares. That is why diagonal beams are found in most half-timbered structures. These diagonal braces, crosses and up braces ensure that the structure cannot subside under the influence of the weight of the roof and the wind. Yet there are also half-timbered structures that have very few braces. Here the strength is obtained by the wood connections themselves and a larger number of often more heavily dimensioned beams. Braces never occur in Japanese half-timbering.

Foundation with self-poured concrete posts

No diagonal braces in Japanese half-timbering!

Tips

- Choose a good location

Take into account weather conditions, which buildings are in your area, etc. Don't forget to apply for a building permit! - Draw out your idea

Put all the ideas, considerations and sketches together and draw out your plan. Make a scale model if necessary. This offers insight for, for example, the choice of wood connections, the correct slope of the roof, etc. You can take the scale model with you where the work is being carried out. If in doubt, discuss the problem using the model. - Number your truss structure

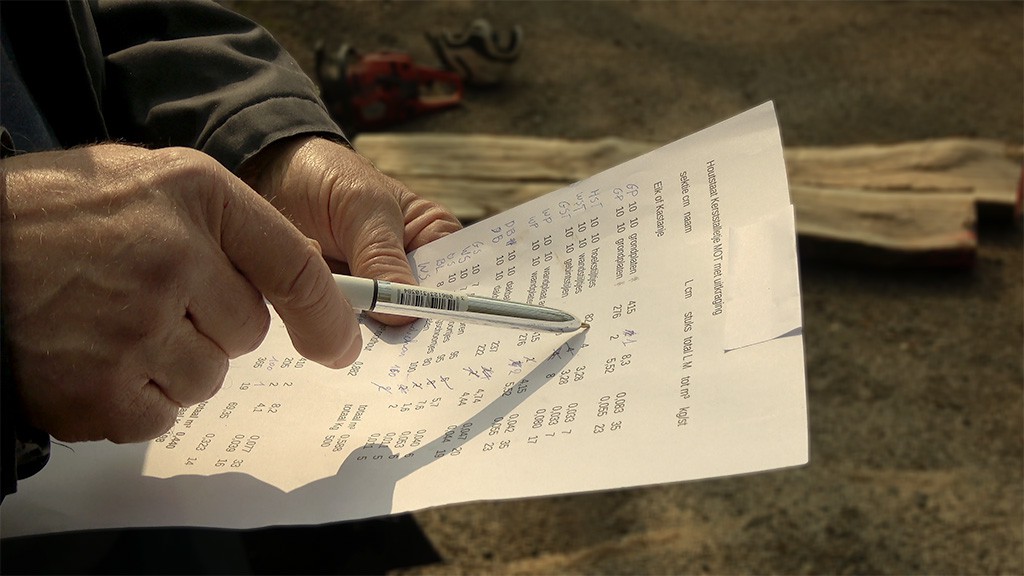

It is always a good idea to number your different trusses on the plan/model and on the wood. If it gets complicated, everyone knows which truss you are talking about. - Make a bill of quantities for the wood

List in detail which wood in the dimensions you need. Don't forget to mention the numbers for recurring elements. Name the different parts with abbreviations (e.g. RB for roof beam...) You can use the bill of quantities to request quotes.

Collecting and inventorying the wood needed: each part is given an abbreviation

The scale model comes in handy when selecting the suitable wood

On the bill of quantities you can check off the selected wood

Carving the marks

Coloring in the marks