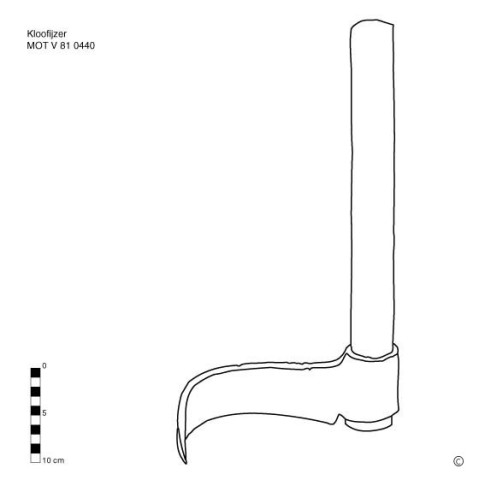

Cleaving iron, froe

The cleaving iron or froe is used to split laths and staves.

When the trunk is sawn into pieces, the craftsman splits a piece into four or eight with a splitting wedge or with a splitting wedge with handle.

Depending on the thickness of the triangular cross-section pieces obtained and the type of laths, these pieces are first divided into two or four with a straight froe or with a hollow froe. To do this, they are clamped in a wooden frame (1). The blade is placed on the cross-section and beaten with a wooden froe-maul. The stem is then pulled down so that the gap widens and the tool can be pushed into it. Then those pieces are split further with a straight froe that is usually less thick and sharper than the first. It is handled in the same way, but the craftsman usually does not use a hammer to drive the tool into the wood. When the lath gets too thick or too thin, he pulls or pushes the stem down or up to cut into the wood. The laths can be split quarter-hourly or flat, i.e. radially or tangentially. (2)

Staves are made with a heavier cleaving iron, which is almost blunt and therefore does not cut the wood. They are cleaved radially.

To be distinguished from the stave splitter. [MOT]

(1) There are different models: WEYNS 1968: 252; JENKINS: fig. 6 etc.

(2) In Flanders the profession of lath maker occurred in Beernem (Sint-Joris-ten-Distel)

Straight cleaving iron or froe MOT V 81.0439

Hollow cleaving iron or froe MOT V 81.0440