Timber selection

There are several factors involved when choosing construction wood:- the application (the nature of the construction and location of the specific part in that construction)

- the properties of the sort of wood

- the availability

Application/expectations

You could always use the most durable and strongest wood for any construction, but sometimes it can be a little less. Not everything has to last forever or be rock solid. A truss of a church or a chicken coop, the expectations are clearly different.Various types of wood are also used within a certain construction. Parts exposed to the elements or close to the ground must be particularly durable, but elements in the interior or in the roof structure may have other requirements, such as specific weight or flexural strength.

The choice for a particular type of wood is therefore always determined based on a series of factors. First you ask the question 'What do I expect from that piece of wood?', then you look at which types of wood have the right properties to meet those expectations.

Properties

Each type of wood has its specific properties that play a role in its processing and practical application. Factors such as orientation (end grain, quarter sawn or flat sawn), durability (resistance to attack by fungi, insects...), physical properties (shrinkage, swelling, mass, moisture content...) and mechanical properties (tensile, compressive, splitting and bending strength, hardness and elasticity) determine which type of wood is most suitable.

In historic half-timbered construction, oak and elm were preferably used for carpentry. However, olm is no longer available today. Oak, chestnut and robinia are durable woods that last a long time, even in direct contact with the ground. Larch is the most sustainable softwood species found in our country. Other coniferous wood such as pine, spruce, poplar, etc. can be used indoors, for example for rafters, battens and the roof.

Image by Pixabay

Availability

In the past, the options for wood transport were much more limited than today and people mainly used types of wood that were locally available. During the Middle Ages, deforestation increased and the timber trade developed more. Wood thus became more available, if you had the money for it. Today, due to increasing globalization, we have access to wood species from all over the world. Yet the cost remains decisive. Ecological motives also play a role: does the wood come from responsibly harvested and sustainably managed forests? Finally, aesthetic, cultural and emotional arguments can also determine our choice of wood. A craftsmanship made of wood from your own forest undoubtedly has added value. The choice of a traditional type of wood such as oak for a traditional construction such as a half-timbered barn is also justifiable.Video: the wood for the nativity scene was cut in the forest, otherwise destined to be firewood

The transport of wood

The basic raw material of half-timbering is of course wood. The felled wood must be brought from the felling site to the yard and logs and beams also often have to be moved on the yard. This can be done without the aid of heavy machinery, using tools and vehicles powered by muscle power.

Carrying is the easiest way to move wood. Some hand tools such as the wood hook and the timber tongs make carrying easier. By carrying together with several people, considerable trunks and trees can be moved.

To roll heavy logs you can use a sappie, cant hook or a ring dog.

Towing is a frequently used technique, especially for tree trunks. A sappie hammered into the trunk can simplify towing, especially with several people together. The towing power of humans is of course limited, with a horse much heavier logs can be towed. A final way to tow with muscle power is to use pulleys or tackles.

If the surface permits, logs and beams can be moved with wheeled vehicles. The "mallejan" (Dutch) or logging wheels are a specialized vehicle in which the trunk is lifted from the ground using the drawbar as a lever in order to drive it. There are large trolleys that are pulled by horses, but smaller ones that are pulled by one or two people can certainly prove useful on the construction site.

Video: wood transport with logging wheels and timber lifting tongs

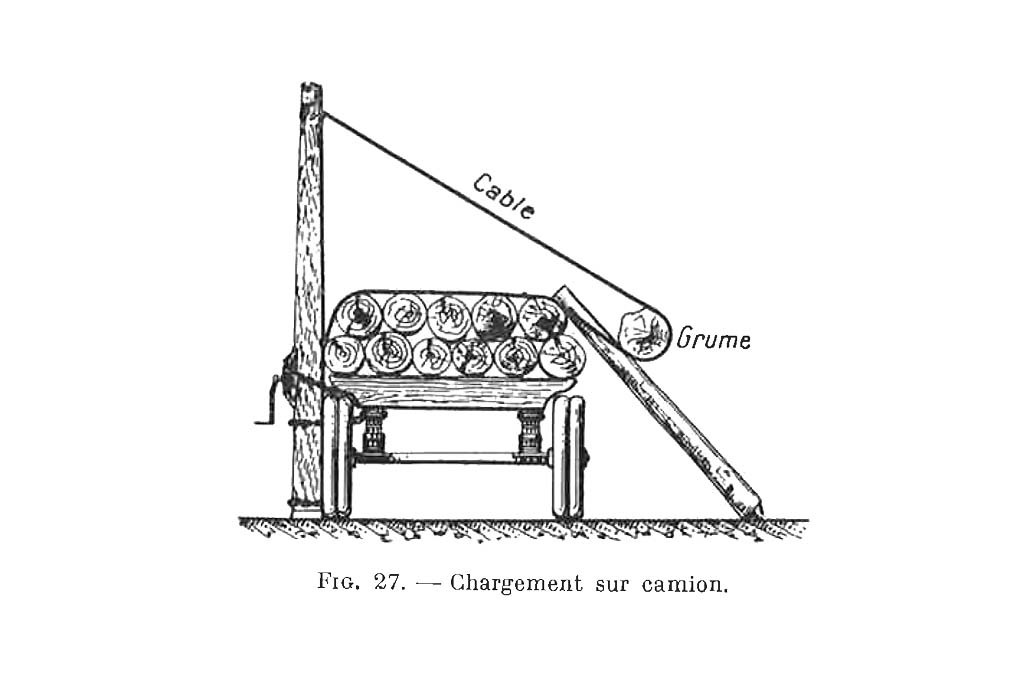

To get logs or beams to a height, for example on a wagon, sloping crossbeams can be used. By placing a rope under the trunk and pulling on the top, the trunk rolls upwards on the beams. This parbuckling technique constitutes a considerable gain in strength. Naturally, this works best with round trunks, but beams can also be rolled upwards.

Before moving logs, they are cut to length with a double-handed cross-cut saw or a one-man cross-cut saw. This means that there is no need for heavier transport than is strictly necessary.

Logging wheels from our collection

Logging wheels in action

© Luc Verachtert

Learn more?

Download De restauratie van een “euts”. Vergelijkende studie van boomezels in Vlaamse musea. Houttransport in binnen- en buitenland by Luc Verachtert (2011)

Principle of parbuckling (from RAZOUS P - 1941.: Cours d'exploitation commerciale des bois, Paris, p. 177)

Hoisting with a wire rope hoist